Company

Sustainable plasticsfor more than 40 years

The Burwinkel company, headed by Martin Burwinkel, has been presenting itself as innovative, flexible and customer friendly for more than 40 years.

It is therefore no wonder that Burwinkel Kunststoffwerk GmbH, with its headquarters in Mühlen, is already one of the leading companies in the plastics industry.

Find new waysto achieve optimum results

Solutions from A to Z

For our customers in Germany and abroad, we offer comprehensive and individual solutions: From the idea and development of an article to its design and production, assembly and printing, we offer everything from one competent source.

Find new ways

In doing so, we do not just go down well trodden paths. In order to achieve optimum results even in the case of new challenges, in research and development we work together closely with competent partners and university institutions. Thanks to this approach, we do not only create new developments and new tools, but we also successfully ensure our own steady growth.

HistoryFrom the beginning

Founding of the company

Initially in Dinklage and a short time later in Lohne / Brockdorf on Zerhusener Straße, Franz Burwinkel started building up his own company.

And Franz Burwinkel remained a technician and tinkerer. As a passionate amateur pilot, he pursued the idea of the design and construction of motor aircraft made of plastic in Brockdorf. His “crazy idea” failed, but will continue to exist as a goal in mind.

Move to Mühlen/Steinfeld

In 1985 the company moved to Steinfeld/Mühlen.

1st Extension

A further two buildings (Hall 3, 4) were built for production and storage.

2nd Extension

Due to the increased demand, two additional buildings had to be erected (Hall 5, 6).

Martin Burwinkel, industrial engineer, has been managing the company in Mühlen since 1996 together with his father Franz.

Burwinkel introduced a quality management system which complies with DIN EN ISO 9001: 2008, confirmed by DQS GmbH.

3rd Extension

The foundations for Hall 7 and 8 were laid.

Brinkmann Formenbau

Foundation of Brinkmann Formenbau GmbH at the Mühlen site. Takeover of the employees of Melz Werkzeugbau.

![]()

4th Extension

The capacities had to be increased once again. Three halls were built (Hall 9, 10, 11). The company Warsawsky was taken over.

EFTEX

The second son, Jens Burwinkel, moved with his plastic company EFTEX in 2004 to the building of the former Warsawsky company at Landwehrstraße in Lohne.

5th Extension

Two further buildings were built at Kötterhof 2 (Hall 12, 13)

Two further buildings were built at Kötterhof 4 (Hall 14, 15)

At the age of 70 the company founder Franz Burwinkel died.

6th Extension

Production in Hall 15 became operational.

7th Extension

Production in Hall 16 became operational.

JobsWe are looking for...

Our company is growing and developing steadily. In order to continue to accomplish outstanding achievements, we are constantly looking for good employees who together with Burwinkel Kunststoffwerk GmbH want to set new standards in the plastics market.

At the moment we are looking for:

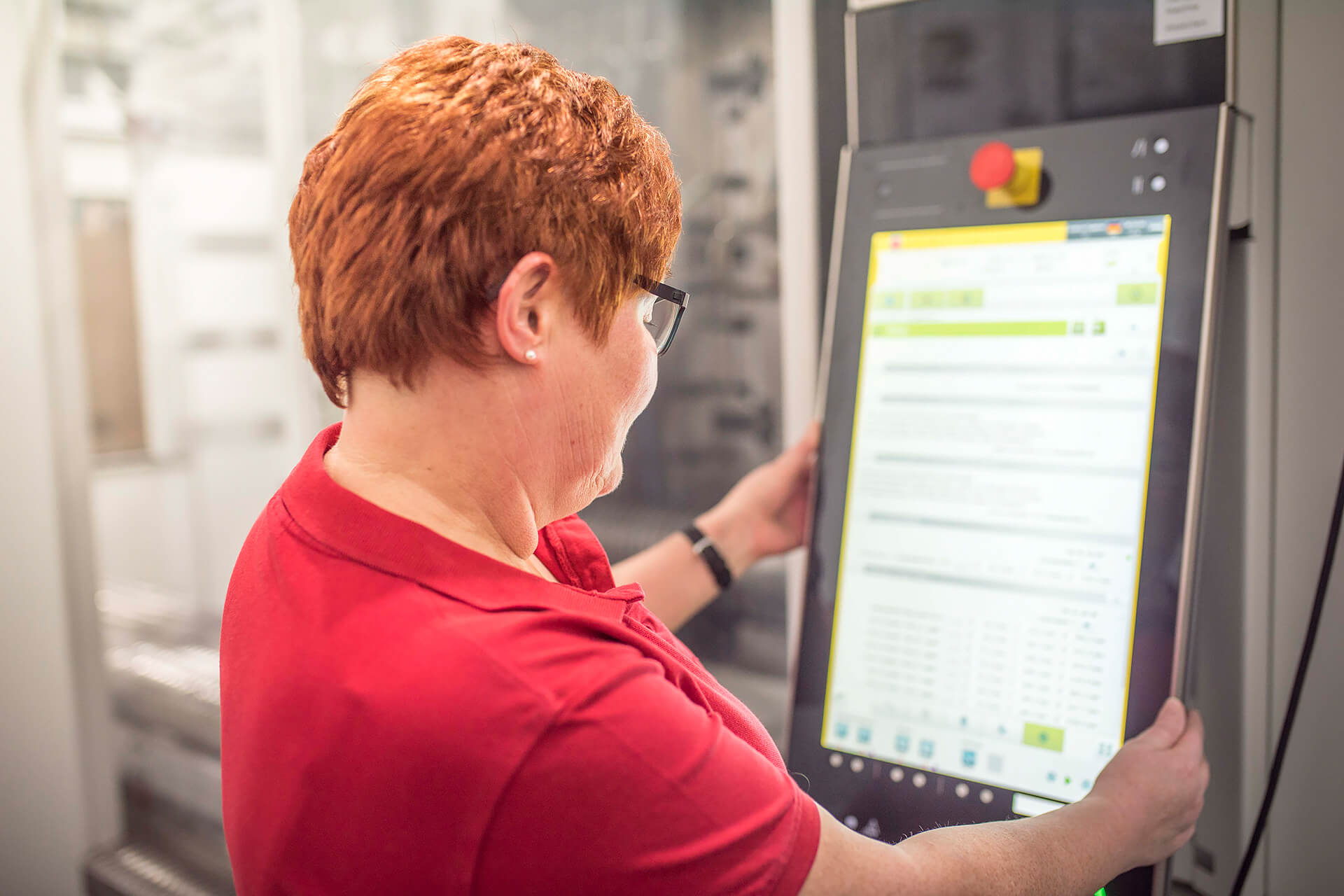

• Process mechanics in plastics and rubber technology (m/f)

• Production assistant (m/f)

• Apprentice process mechanic (m/f)

• Specialist for warehouse logistics (m/f)

Are you interested? Then send your complete and relevant application documents to:

Burwinkel Kunststoffwerk GmbH | Rienshof 7 | D – 49439 Steinfeld/Mühlen

PartnerCooperation and working together

Our success is also thanks to the merit of our competent partners. Our projects can only be completed by successful cooperation and working together. We would therefore like to thank our partners and wish for a continued successful partnership.

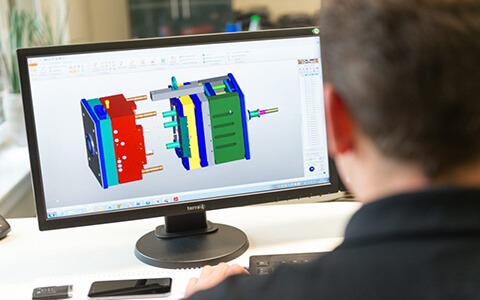

Innovative designs, modern production methods, complex single and mass production – Brinkmann Formenbau is a competent partner in the field of mould making, tooling and erosion technology.

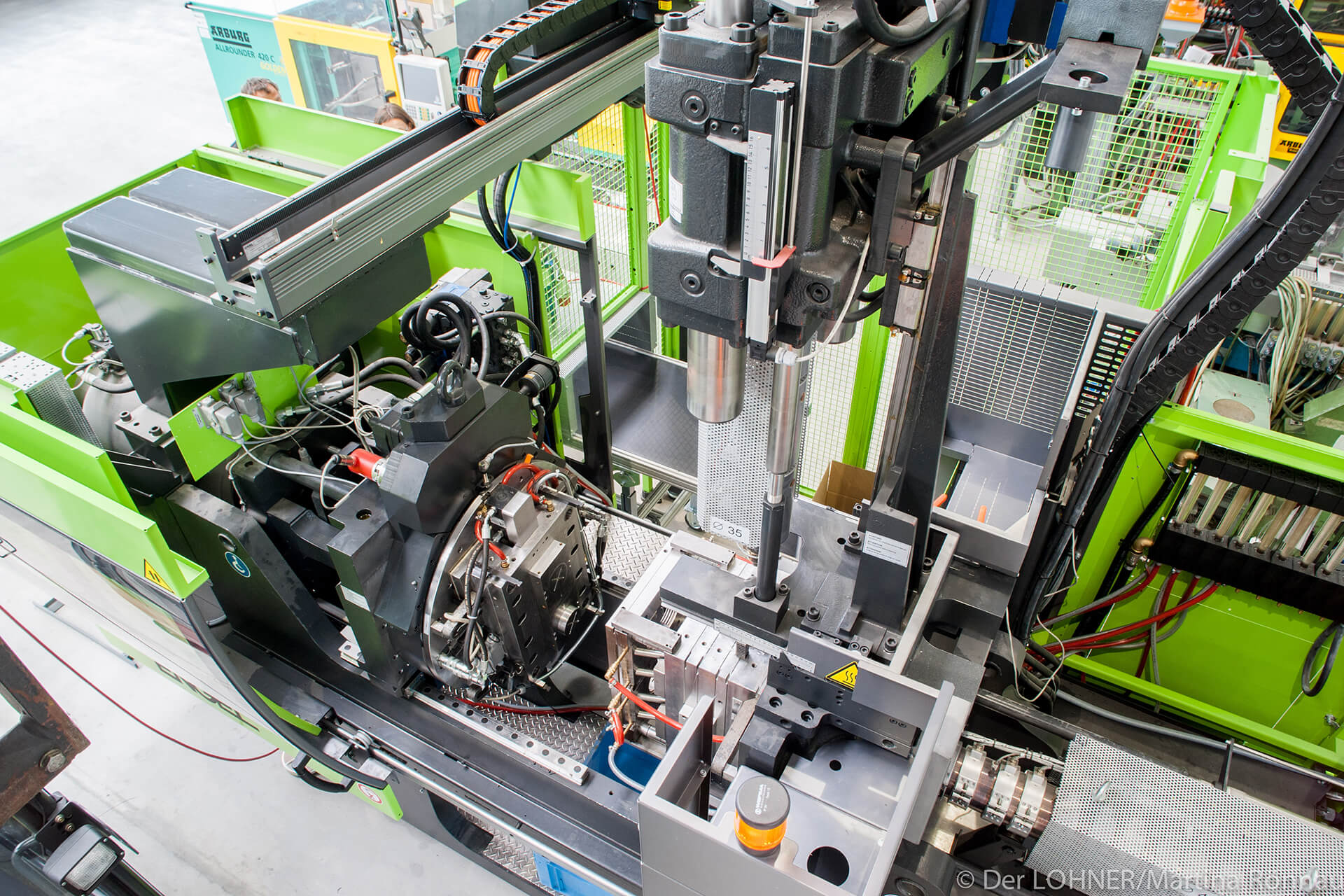

EFTEX Zubehör GmbH is our partner in the field of mass production with high unit numbers. Injection moulding of the highest quality and variety – that is the challenge that joins our companies together.

As a responsible company, we rely on Lohnre Kunststoffrecycling GmbH in the field of plastic recycling. Individual processing concepts enable us to process our production waste in a professional and proper manner.

With ZWT, the Centre for Materials and Technology in Diepholz, we have an independent partner in the following areas:

– Material testing

– Material assessments

– Research and development

– Qualification and advanced training of our specialists

We rely on DQS GmbH to plan, control and monitor our business processes. With them as an independent management partner, we can coordinate and organise all workflows in our company as best as possible.

ReferencesExamples of our work

Wie produziert man eigentlich Gezwitscher?So wie wir.

Wie bringt man eigentlich lecker in Form?So wie wir.

Wie verpackt man eigentlich Seifenblasen?So wie wir.

Wie macht man eigentlich Hilfe aus Kunststoff?So wie wir.